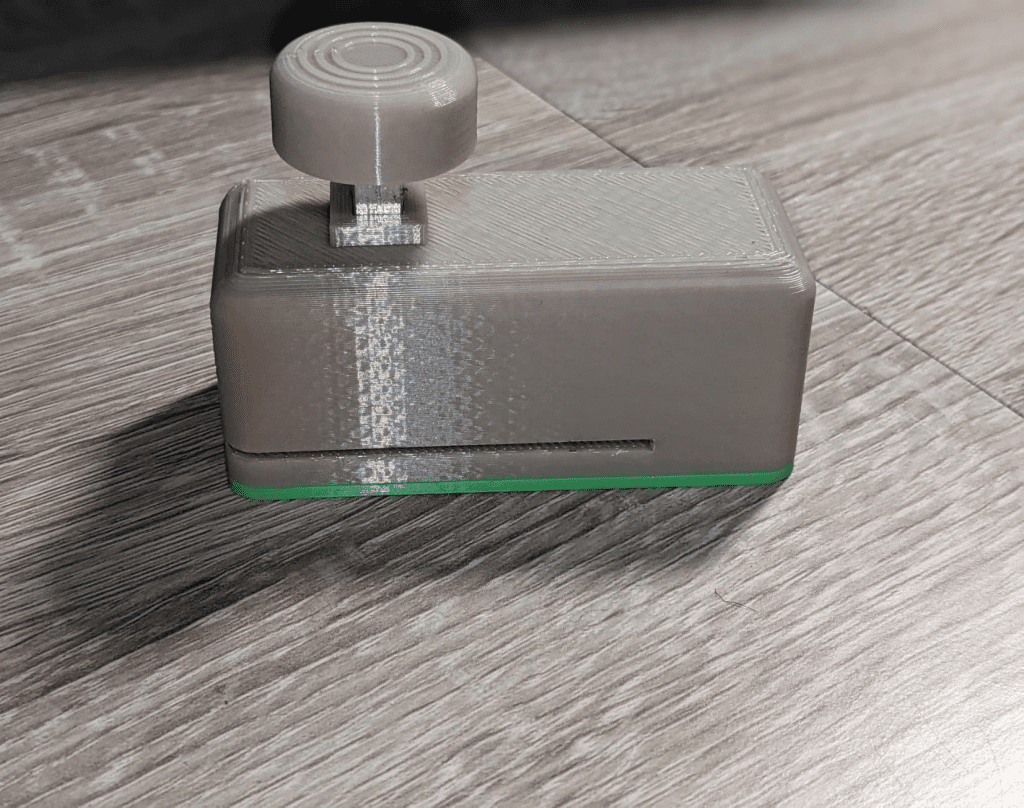

You’ve probably never seen anything like this before. Its function is as unique as its design. Want to know what it’s for?

What Is a Disk Notcher?

A disk notcher might not be a household name, but its impact on various industries is undeniable. This specialized tool is designed to create precise notches in disks or circular materials, enabling them to fit seamlessly into other components. Whether you’re working with metal, plastic, or even wood, a disk notcher ensures clean, accurate cuts that save time and effort.

The unique combination of its function and design makes it a standout tool for professionals in manufacturing, engineering, and even creative fields. But what exactly sets this tool apart from others? Let’s dive into its features and applications.

How Does a Disk Notcher Work?

At its core, a disk notcher operates by applying a combination of force and precision to create notches in circular materials. The tool’s sharp, durable blade or punch mechanism allows it to cut into disks without causing damage to the rest of the material. Think of it like using a cookie cutter, but instead of dough, you’re working with sturdy materials that demand pinpoint accuracy.

Most disk notchers come with adjustable settings, allowing users to customize the depth and angle of the notches. This versatility is why they’re indispensable in industries requiring high precision.

Applications of a Disk Notcher

Disk notchers may not be the most glamorous tool, but their uses are wide-ranging and incredibly practical. Here are a few key applications:

- Manufacturing and Assembly: In industries like automotive and aerospace, disk notchers play a critical role in creating parts that need to fit together flawlessly. The precision of the notches ensures proper alignment and functionality.

- Metalworking: For machinists and metalworkers, a disk notcher is essential when fabricating components for machinery or structural projects. Its ability to cut cleanly through tough materials makes it a go-to tool.

- Creative Fields: Artists and designers often use disk notchers to create intricate designs or custom pieces. Whether working with metal or plastic, this tool helps bring creative visions to life.

- Repair and Maintenance: Professionals in maintenance rely on disk notchers to modify existing parts, allowing for quick and effective repairs without needing to replace entire components.

Why the Disk Notcher Stands Out

The disk notcher’s unique design and functionality make it a valuable addition to any toolkit. Here are some reasons why it’s a game-changer:

- Precision: The ability to make exact cuts ensures that the finished product is both functional and aesthetically pleasing. This level of precision is hard to achieve with traditional tools.

- Versatility: From metals to plastics, a disk notcher can handle a variety of materials. Its adjustable settings make it adaptable for different projects and industries.

- Durability: Built to last, these tools are made from high-quality materials that can withstand the rigors of frequent use.

- Efficiency: By automating the notch-making process, a disk notcher saves time and reduces the risk of errors, increasing productivity for professionals.

Types of Disk Notchers

Depending on your needs, there are different types of disk notchers available on the market. Here’s a quick overview of the most common ones:

- Manual Disk Notchers: These are operated by hand and are ideal for smaller projects or situations where portability is essential.

- Electric Disk Notchers: Powered by electricity, these tools are perfect for larger-scale operations that require speed and consistency.

- Hydraulic Disk Notchers: Designed for heavy-duty applications, hydraulic notchers deliver immense force, making them suitable for thick or hard materials.

- Customizable Models: Some manufacturers offer customizable options, allowing users to modify the tool for specific projects or industries.

How to Choose the Right Disk Notcher

Selecting the right disk notcher depends on several factors, including the type of material you’re working with, the scale of your project, and your budget. Here are a few tips to help you make the best choice:

- Material Compatibility: Ensure the tool you choose can handle the materials you’ll be working with most frequently.

- Durability: Look for models made from high-quality materials to ensure longevity.

- Ease of Use: If you’re new to disk notchers, opt for a model with straightforward controls and user-friendly features.

- Budget: While disk notchers are an investment, there are models available for every price range. Consider your needs and find a tool that offers the best value.

Maintaining Your Disk Notcher

Like any tool, a disk notcher requires proper maintenance to ensure its longevity and performance. Here are some simple tips to keep yours in top condition:

- Regular Cleaning: Remove debris and residue after each use to prevent build-up that could affect functionality.

- Blade Maintenance: Sharpen or replace the blades as needed to maintain precision cuts.

- Lubrication: Apply lubricant to moving parts to reduce wear and tear.

- Storage: Store the tool in a dry, cool place to prevent rust or damage.

A Tool That Delivers Every Time

Whether you’re a seasoned professional or a hobbyist, a disk notcher is a tool worth considering. Its ability to combine precision, efficiency, and versatility makes it indispensable in a wide range of applications. From creating intricate designs to ensuring seamless functionality in industrial components, the disk notcher delivers results that are both reliable and impressive.

Conclusion

The disk notcher might not be the flashiest tool, but it’s a workhorse that has earned its place in many industries. Its unique design and precision functionality make it an essential companion for anyone tackling projects that require clean, accurate notches. With its combination of versatility, durability, and efficiency, the disk notcher is proof that sometimes, the simplest tools can make the biggest impact. So, whether you’re an artist, engineer, or repair technician, consider adding this powerhouse to your toolkit—it’s a decision you won’t regret!